Intervention free Subsea Completion

Challenge

A major operator on the Norwegian Continental Shelf (NCS), issued a completion development tender - their goal was to avoid intervention and create safer working conditions. The challenge was to develop a “disappearing” plug with a bypass function. To do this the plug needed to remotely close the bypass and establish an ISO 14310 V0 / ISO 28781 V1Q1 rated shallow barrier after a light fluid had been displaced in well, the packer set, and completion tested. Following the VXT installation, the plug “disappears” by applying pressure cycles to remotely open it. This is done by an ROV, pumping skid directly onto the VXT, from a Floating Production Storing and Offloading (FPSO) vessel, directly from the rig or from a fixed installation.

Solution

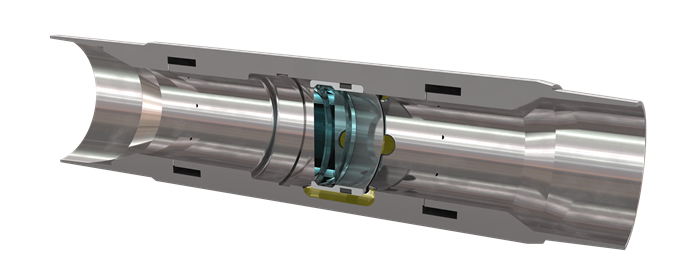

Interwell was awarded the contract following the successful development of the Inter Remote Bypass Valve (IRBV). In close collaboration with the operator, Interwell managed to develop and qualify the product in less than a year.

The IRBV is a glass plug with a circulation bypass, which enables circulation down tubing when finishing completion activities. With pressure cycles the bypass can be closed to establish a V0 qualified barrier. This requires no further intervention to remove since it uses pressure cycling to remotely open barriers.

Operational Key Points:

IRBV was installed, cycled closed and tested May 18th, 2019

- Used 1.08 sg Packer Fluid

- To close IRBV – pressure cycles from 2 to 117 bar

- Valve closed on cycle as intended and at expected pressure:

67 bar surface pressure - IRBV inflow test: ~61 bar

- IRBV pressure test: from above to 484 bar surface pressure

IRBV was successfully cycled open June 26th, 2019

- Used 1.03 sg seawater

- To open IRBV: pressure cycles from 40 to 220 bar

- Plug opened on cycle as intended and at expected pressure: 80 bar

Increased Value

This project successfully achieved the goal of avoiding intervention and generating safer working conditions. In line with the target, Interwell’s IRBV eliminated the need for intervention and work over riser on the rig for pulling the BOP and installing a VXT. This resulted in reduced cost and time.