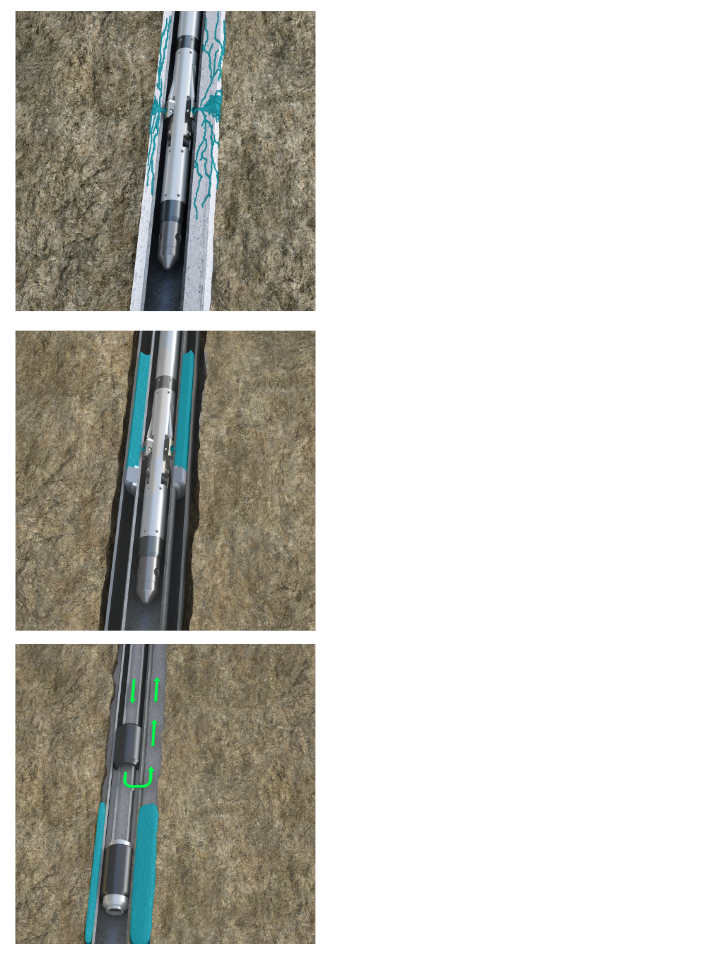

Whether it’s mitigating sustained casing pressure or providing a remedial integrity barrier, the successful restoration of well integrity can unlock revenue potential and extend the life of your well. Through the precise delivery of our patented epoxy sealent into the micro annulus or by using it to seal off a leaking production packer we can help you re-establish well integrity.

Benefits

- Unaffected by contamination.

- Extends field life and improves recovery

- Mitigates sustained casing pressure

- Can provide a remedial integrity barrier

- Suitable for all applications including horizontal wells

- Solidifies under well temperature conditions sealing perforated holes – eliminating the need for patching

- When injecting into a cement matrix for micro-annulus repair, a pumping differential pressure of 200bar is achievable.

For more information please contact our sales department

View related Case Studies:

Restoring Integrity to an Unconventional Cement Packer Design

Epoxy Injection in Gravel-Pack to Shut Off Water Producing Zones and Extend Production Lifetime