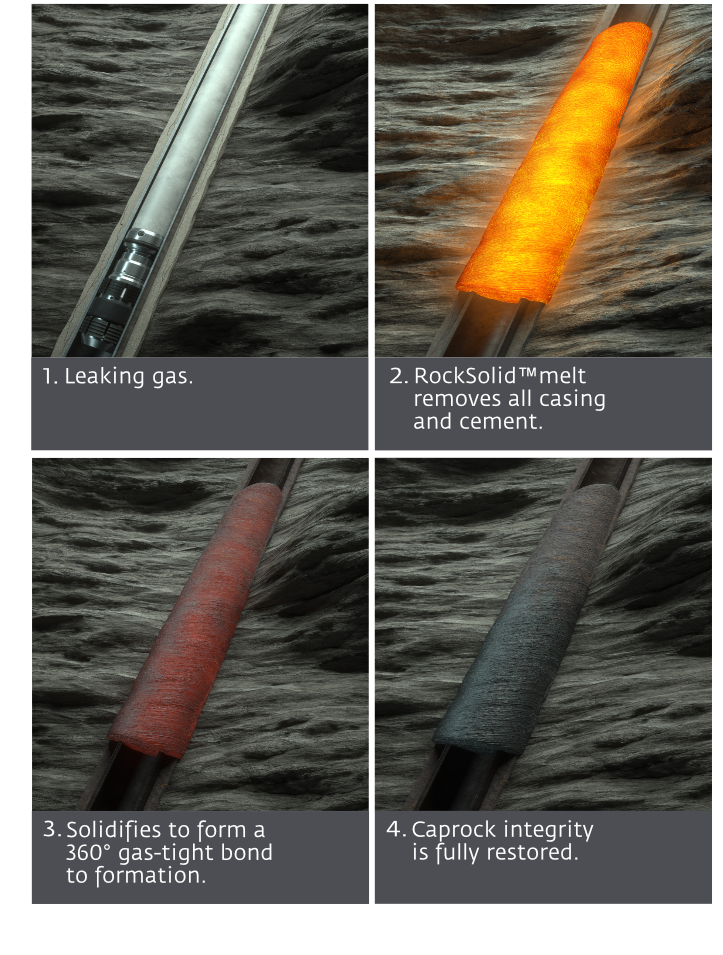

Through the pioneering use of THERMIT®, it melts casing and cement, removing all wellbore elements. These then solidify into an impermeable, rock-to-rock, gas-tight barrier - across the entire well cross-section permanently.

It’s the only Plug and Abandonment (P&A) solution that is run rigless in a single trip, using fewer resources and unprecedented material quality. Traditional pressure control equipment and a pressure vessel is required on site, but with modular tools it can be mobilised easily to any wellsite.

Evidenced by our success rate, RockSolid™ enables you to maximise your confidence with predictive costs and results and take control of your P&A program.

As pioneers of thermite technology, we have the experience, knowledge and capability to deliver a truly unique solution unmatched in quality.

View related Case Studies:

RockSolid™ barrier system is a success

Contact us to learn more:

Christian Rosnes - P&A Commercial Manager

Email: chro@interwell.com

Tel: +1 825 438 0016

For Technical Enquiries

Stian Tøndel - Technical Manager P&A

Email: st@interwell.com

Tel: +47 992 91 214